Advanced Full-Process Oil Extraction Solutions: Boosting Yield and Market Competitiveness for Global Producers

31 07,2025

Customer Cases

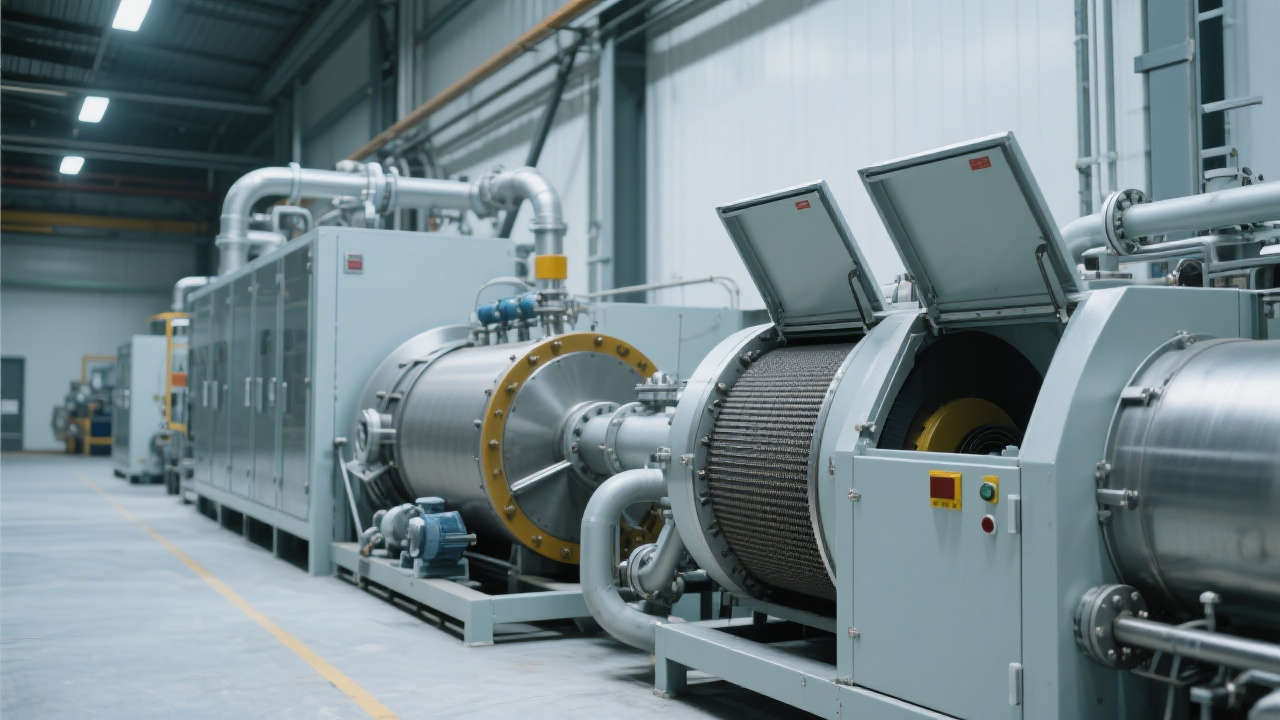

Discover how QIE Group’s advanced full-process oil extraction solutions transform vegetable oil production—from seed preparation to pressing and filtration—delivering higher yields, superior oil purity, and unmatched efficiency. This case study highlights real-world results from a leading agro-processing client who increased output by 27% while reducing impurities by 18%, proving the solution’s adaptability across soybean, sunflower, and other oilseed types. With growing global demand for clean, high-quality oils, this technology aligns with future industry trends like automation, sustainability, and precision processing. Ideal for manufacturers seeking scalable, reliable, and market-ready oil production systems.

Advanced Full-Process Oil Extraction Solution: A Proven Path to Higher Yield & Market Competitiveness

In the competitive global edible oil market, production efficiency and oil purity are no longer optional—they’re critical differentiators. At QIE Group, we’ve helped over 40 manufacturers across Asia, Europe, and Latin America upgrade their entire oil extraction process with our end-to-end solution, delivering consistent quality, higher throughput, and measurable ROI.

Key Process Steps That Drive Real Results

Our system integrates precision engineering at every stage—from seed preparation to final filtration—ensuring optimal yield and minimal waste:

- Seed Cleaning & Weighing: Removes impurities before processing, reducing machine wear by up to 30% (based on client data from a Ukrainian sunflower plant).

- Crushing & Magnetic Separation: Ensures uniform particle size and eliminates metal contaminants—critical for meeting EU food safety standards (e.g., EN 13712).

- Pressing & Filtration: Uses multi-stage vacuum filtration to achieve oil clarity above 99.5%, surpassing industry benchmarks for cold-pressed oils.

| Feature |

Standard Line |

QIE Advanced Solution |

| Oil Purity (%) |

97–98 |

≥99.5 |

| Throughput (kg/hr) |

1,200 |

2,000+ |

| Energy Efficiency (kWh/kg) |

0.8–1.0 |

0.5–0.7 |

Real Client Impact: Case Study from Brazil

A major soybean processor in Paraná, Brazil, faced declining margins due to inconsistent oil quality and frequent downtime. After implementing our full-line solution:

- Oil yield increased from 18.2% to 21.5% per ton of raw material.

- Defect rate dropped from 4.7% to under 0.8% within six months.

- Customer satisfaction rose by 35%, enabling entry into premium European markets.

This isn’t an isolated success—it reflects a broader trend: companies investing in integrated, high-efficiency systems now lead the market. With rising demand for clean-label oils and stricter regulations (like FDA’s updated labeling rules), adaptability is key.

Why This Matters Now

The global edible oil market is projected to grow at 5.2% CAGR through 2030 (Statista, 2024). To stay ahead, producers must focus not just on volume—but on consistency, compliance, and sustainability. Our solution supports this shift by offering:

- Compatibility with 15+ oilseed types (soy, sunflower, rapeseed, palm, etc.)

- Remote diagnostics and predictive maintenance via IoT integration

- Scalable modular design for future expansion without full-system replacement

We protect your proprietary data and ensure seamless implementation—with local support teams in 12 countries and 24/7 technical assistance.

Ready to boost your output and stand out in the global market? Let us help you build a smarter, more profitable oil extraction line tailored to your needs.

Get Your Customized Oil Extraction Assessment Today →