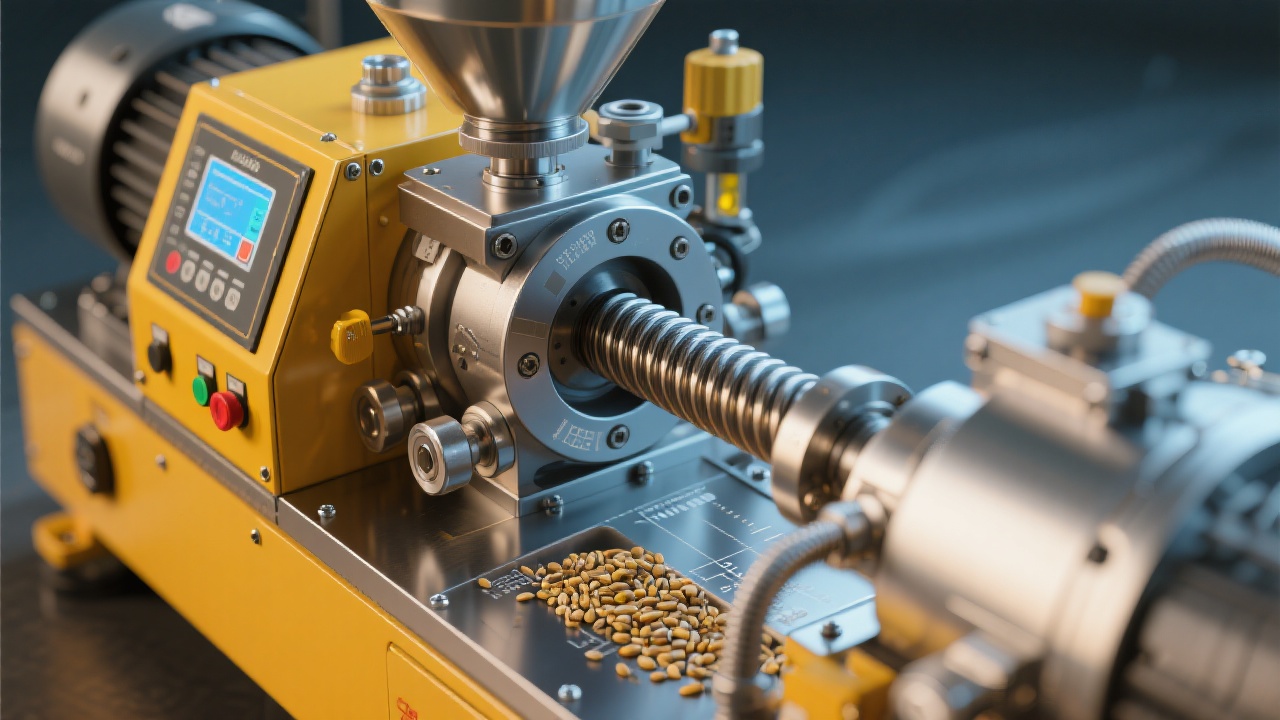

For decades, the dehydration (or "degumming") stage has been a critical yet often overlooked step in edible oil refining. While many processors focus on refining efficiency or energy savings, few realize that up to 15–20% of final yield loss can stem from poor degumming control—especially when moisture levels, temperature variance, and mixing intensity are not tightly managed.

Water content must be precisely controlled during degumming—typically between 0.1%–0.5% depending on oil type. Too little water leads to incomplete phospholipid removal; too much causes emulsification, increasing separation time and reducing throughput. A study by the International Society of油脂 Chemists (ISOC) found that even a ±0.2% deviation in water addition can result in a 7–12% increase in gum residue, directly impacting downstream filtration and bleaching performance.

| Control Variable | Ideal Range | Impact of Deviation |

|---|---|---|

| Moisture Addition | 0.1–0.5% (w/w) | Low = incomplete removal; High = emulsion formation |

| Temperature | 45–55°C | Too low = slow reaction; Too high = thermal degradation |

| Mixing Intensity | 200–300 rpm | Excessive = foam; Insufficient = uneven hydration |

| Settling Time | 15–30 min | Short = incomplete phase separation |

A mid-sized sunflower oil processor in Ukraine reduced gum content from an average of 280 ppm to under 120 ppm after implementing a standardized SOP based on real-time conductivity monitoring. By replacing manual sampling with inline sensors measuring electrical conductivity (a proxy for free water), they eliminated human error in endpoint detection—a common cause of over-processing or under-processing.

This shift wasn’t just about consistency—it boosted their monthly output by 8–10% without additional capital investment, thanks to faster batch cycles and fewer rework instances.

Not all oils behave the same. Soybean oil requires higher water dosing (~0.4%) due to its phospholipid profile, while rapeseed oil may need lower temperatures (45°C) to avoid premature oxidation. Customized recipes—not one-size-fits-all—are key to achieving optimal results across diverse feedstocks.

Modern smart systems now integrate predictive algorithms that adjust parameters dynamically based on incoming raw material quality, ensuring consistent outcomes even as feedstock variability increases seasonally.

If you're ready to move beyond guesswork and embrace precision-based degumming, it’s time to rethink your equipment strategy. The future isn't just automation—it's intelligent integration of data, process knowledge, and tailored engineering.

Get a free technical consultation from our team of food-grade oil processing specialists.

Explore Our Smart Degumming Solutions →