De-gumming is often the first step in edible oil refining—but it’s far from simple. Properly removing phospholipids, free fatty acids, and trace metal ions (like iron and copper) not only improves oil clarity but also enhances shelf life, oxidative stability, and overall quality. In fact, studies show that effective de-gumming can reduce downstream processing costs by up to 15% and improve final yield by 2–4%.

Water-phase de-gumming (also known as wet de-gumming) uses controlled water addition at 60–70°C to hydrate and precipitate phosphatides. This method works best for soybean, sunflower, and rapeseed oils—where phosphorus content ranges from 300–800 ppm. For high-phosphorus oils like cottonseed or corn germ oil, acid de-gumming (using citric or phosphoric acid at pH 3.5–4.0) is more efficient, reducing residual phosphorus to below 50 ppm.

| Oil Type | Recommended Method | Optimal Temp (°C) | Key Parameter |

|---|---|---|---|

| Soybean | Water-phase | 65 ± 2 | pH 6.5–7.0 |

| Cottonseed | Acid | 70 ± 3 | pH 3.8–4.0 |

| Canola | Water-phase | 60 ± 2 | Mixing speed: 150 rpm |

One common issue manufacturers face? Oil becoming cloudy after de-gumming. This usually stems from improper temperature control or insufficient settling time—typically caused by rapid cooling or inadequate coalescence tanks. A real-world case from a Malaysian refinery revealed that increasing settling time from 30 to 60 minutes reduced cloudiness by over 70%, leading to smoother downstream processing.

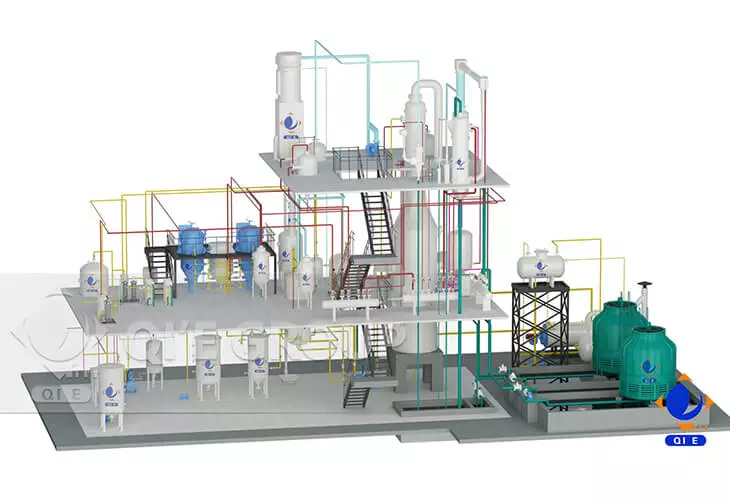

Even with perfect chemistry, poor equipment design leads to inconsistent results. That’s where our partners at Penguin Group come in—they offer fully automated de-gumming systems with real-time monitoring of temperature, pH, and viscosity. Their modular reactors allow quick switching between water-phase and acid methods without downtime, saving an estimated 8–12 hours per month in changeover time.

For food-grade facilities aiming for ISO 22000 or HACCP compliance, their systems integrate seamlessly with existing PLC controls and provide full traceability logs—a must-have for global export markets.

Ready to optimize your de-gumming process? Let us help you choose the right system based on your raw material type, production scale, and quality goals.

Get Your Free Process Audit Today