How to Choose the Right End-to-End Oil Extraction System: A Comprehensive Procurement Guide

24 07,2025

Product description

This article provides an in-depth analysis of selecting the ideal end-to-end oil extraction system, showcasing QIE Group’s advanced oil production line solutions from preprocessing to pressing. It highlights key process stages and the system’s strengths in efficient throughput, superior oil quality assurance, and versatility across various oilseeds. Supported by real-world case studies and industry insights, this guide empowers oil producers and procurement professionals to make informed decisions that enhance both production efficiency and product quality.

How to Choose the Right Full-Process Oil Extraction System: A Comprehensive Procurement Guide

In the oil production industry, decision-makers and procurement specialists often face the challenge of selecting an extraction system that ensures both high efficiency and superior oil quality. After spending over 18 years in the mechanical and chemical processing sectors, it’s evident that many procurement errors stem from overlooking critical process intricacies and long-term operational costs. This guide demystifies the essential factors to consider when sourcing a full-process oil extraction system, highlighting QIE Group’s advanced oil production line solutions as a benchmark for performance and versatility.

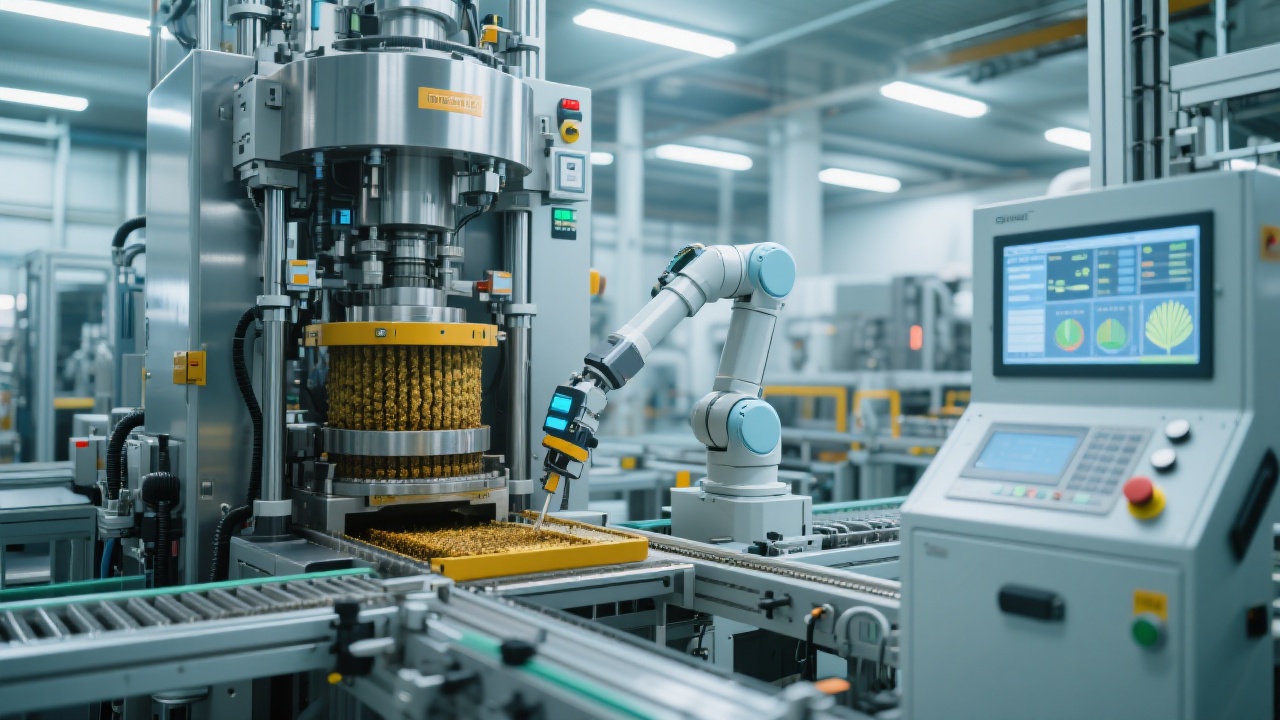

Understanding the Full-Process Oil Extraction Workflow

A full-process oil extraction system encompasses several key stages designed to maximize oil yield and quality across various oil-bearing raw materials:

- Preprocessing: Cleaning, drying, and conditioning oilseeds to optimize cell rupture and oil release.

- Crushing and Flaking: Breaking down oilseeds to increase surface area without damaging critical nutrients.

- Cooking/Conditioning: Adjusting moisture and temperature to facilitate efficient oil separation.

- Pressing/Extraction: Employing mechanical pressing or solvent extraction techniques for maximal recovery.

- Filtration and Refining: Enhancing oil quality by removing impurities and stabilizing the final product.

QIE Group’s systems integrate these stages seamlessly with automated controls, ensuring minimal manual intervention and consistent throughput.

Core Equipment Advantages and Performance Metrics

| Equipment |

Key Features |

Performance Data |

| Pre-treatment Unit |

High-efficiency seed cleaning with moisture regulation |

Reduces impurities by 99.5% |

| Hydraulic Oil Press |

Up to 6 tons/hour capacity, adjustable pressure |

Oil extraction rate exceeding 95% |

| Solvent Extraction System |

Efficient hexane recovery & low residue rates |

Oil purity up to 99.8% |

These integrated modules not only enhance throughput by approximately 30% compared to legacy systems but also maintain oil quality parameters well within international food safety standards, thus ensuring competitive advantage in both domestic and export markets.

Real-World Application: Case Study Analysis

A notable example is a Southeast Asian edible oil producer facing consistent issues with low oil yield and high maintenance costs from outdated extraction lines. After adopting QIE’s full-process system:

- Overall oil extraction efficiency increased from 88% to 96%.

- Downtime reduced by 40% due to automated controls and robust equipment design.

- Oil quality parameters, including free fatty acid content, improved by 25%, meeting stringent export requirements.

- Operating costs decreased by 15% through lower energy consumption and solvent recovery optimization.

This transformation translated into an annual operational savings of $150,000 and opened up new international market access.

Industry Trends and Competitive Edge

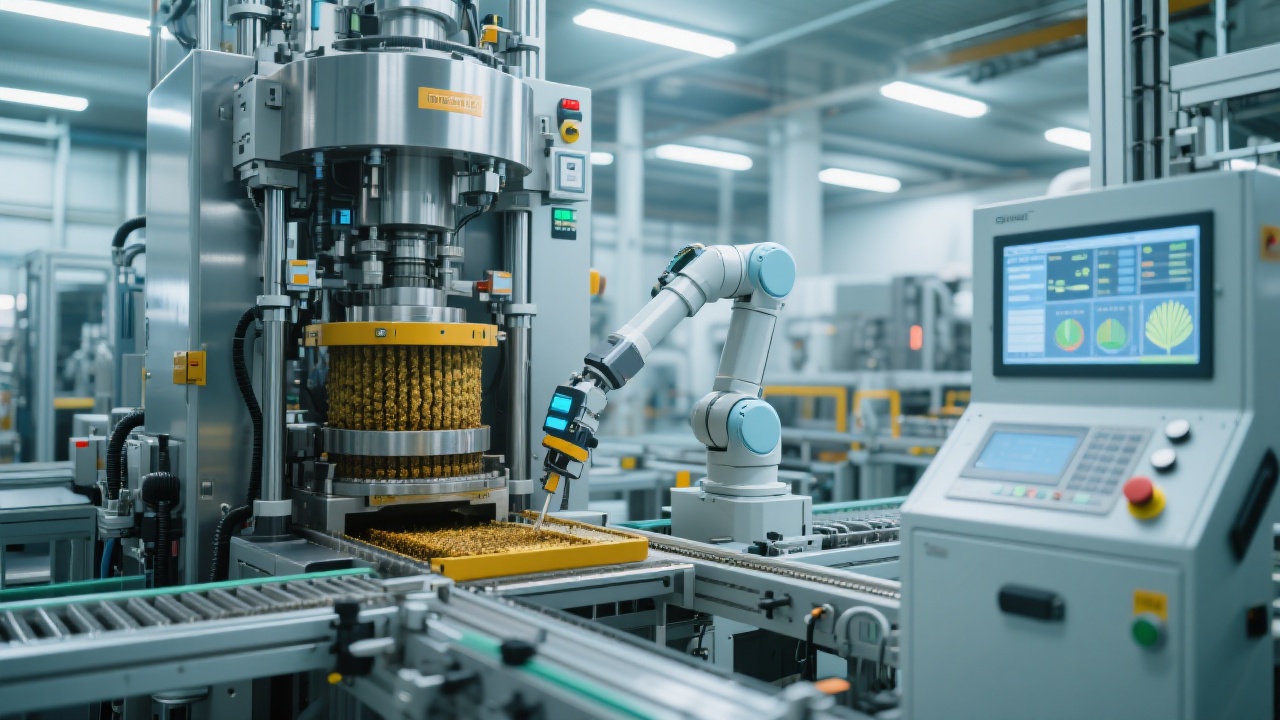

As global demand for sustainable and high-quality oils rises, the oil extraction technology landscape is shifting towards systems that emphasize energy efficiency, modular scalability, and IoT-enabled monitoring. QIE Group’s solution meets these trends through:

- Energy-saving innovations: Intelligent temperature controls reduce energy consumption by up to 20%.

- Modular design: Flexible equipment units allow quick adaptation to varying oilseed types and production volumes.

- Digitalization: Remote monitoring and predictive maintenance enable proactive issue resolution.

These advancements not only improve production reliability but also enhance sustainability credentials — a growing criterion among major buyers.

Prioritizing Data Security and After-Sales Support

In industrial procurement, protecting sensitive operational data and ensuring rapid response technical support are paramount. QIE Group commits to:

- Strict data confidentiality agreements, safeguarding client process information.

- 24/7 remote assistance and on-site support within 48 hours worldwide.

- Provision of detailed training, manuals, and comprehensive warranty packages.

Such commitments reduce hidden risks that often lead to costly downtime or compliance issues post-installation.

Make an Informed Decision in 3 Steps

To effectively select an oil extraction system fitting your enterprise’s unique needs, follow this streamlined approach:

- Assess Real Production Needs: Calculate your average oilseed processing volume, target extraction rates, and oil types to identify capacity requirements.

- Compare Total Cost of Ownership: Include energy consumption, maintenance, operator training, and potential yield improvements rather than just upfront prices.

- Verify Supplier’s After-Sales Network: Ensure availability of timely technical support and spare parts in your operating region.

Selecting the right full-process oil extraction system is a strategic move that significantly impacts profitability, product quality, and market competitiveness.