In the edible oil processing industry, degumming is a crucial step that significantly impacts the quality and efficiency of production. This article delves into how precise control of key process parameters such as temperature and stirring can lead to an efficient and stable degumming process for edible oils.

The degumming process of edible oils is influenced by several core factors, including temperature, stirring intensity, moisture addition, and sedimentation time. For example, research shows that maintaining the temperature within a specific range (e.g., 60 - 70°C for most common oils) can significantly improve the separation of gums from the oil. The stirring intensity also plays a vital role. A moderate stirring speed of around 100 - 150 rpm can ensure uniform mixing of the oil and the degumming agent.

| Control Factor | Optimal Range | Impact on Degumming |

|---|---|---|

| Temperature | 60 - 70°C | Improves gum separation |

| Stirring Intensity | 100 - 150 rpm | Ensures uniform mixing |

| Moisture Addition | 2 - 3% of oil volume | Aids in gum aggregation |

| Sedimentation Time | 2 - 4 hours | Allows gums to settle |

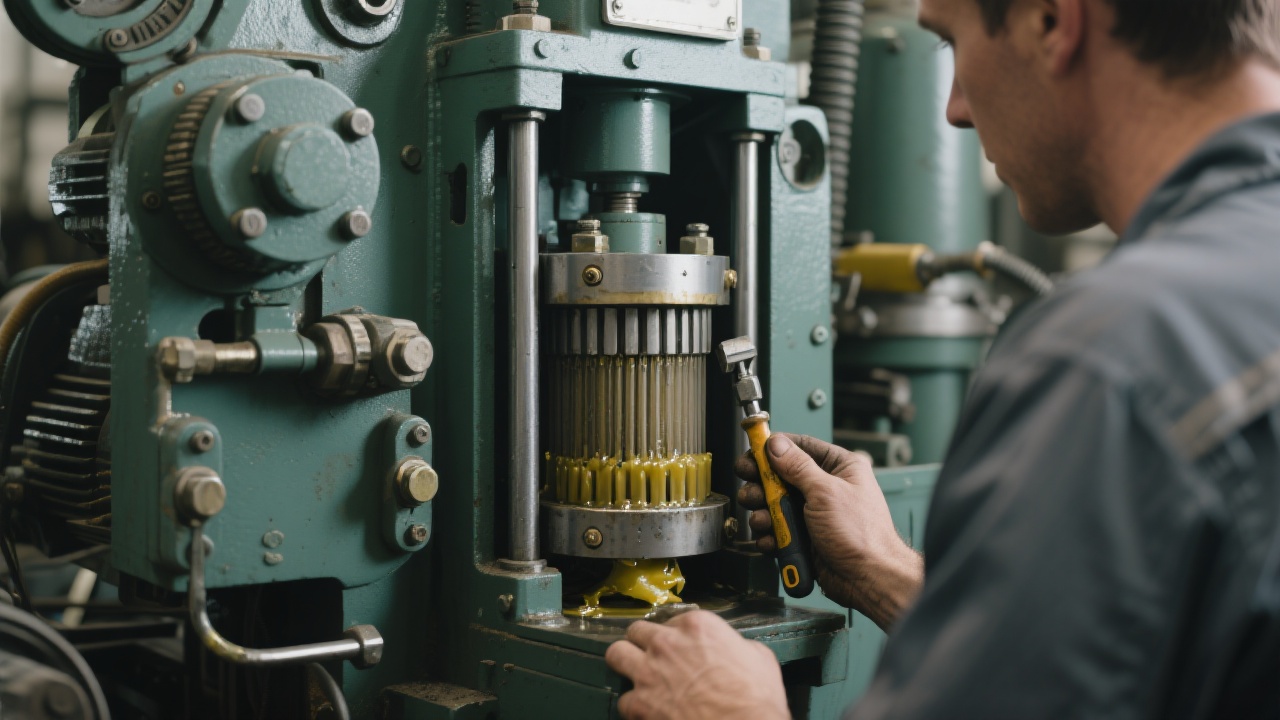

To reduce human errors and ensure consistent degumming quality, it is essential to establish a Standard Operating Procedure (SOP). An SOP clearly defines the steps, parameters, and responsibilities in the degumming process. For instance, it specifies the exact amount of moisture to be added, the temperature range to be maintained, and the stirring time and speed. By following an SOP, companies can avoid common mistakes such as misjudging the end - point of degumming and uneven mixing in equipment.

Different types of oils have different characteristics, especially in terms of their phospholipid content. For example, sunflower oil has a relatively high phospholipid content. For such oils, a more aggressive degumming approach may be required. This could involve increasing the moisture addition slightly (e.g., up to 3 - 4% of the oil volume) and adjusting the temperature and stirring intensity accordingly.

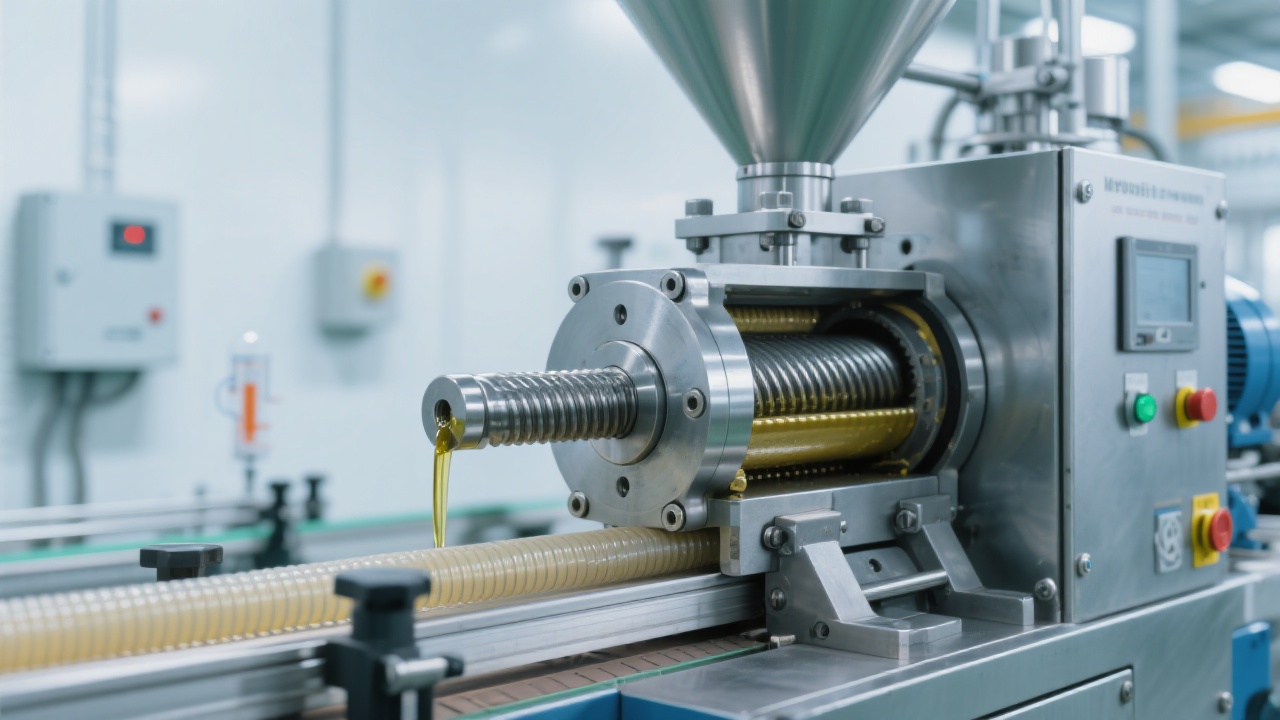

Modern online detection technologies, such as online conductivity monitoring, have revolutionized the degumming process. Conductivity monitoring can provide real - time information about the degumming progress, allowing operators to make timely adjustments. By integrating these technologies, companies can achieve intelligent management of the degumming process, improving production efficiency and the consistency of the final product quality.

We offer state - of - the - art equipment solutions for precise degumming control. Our equipment is designed to meet the diverse needs of edible oil processing companies, with features such as accurate temperature control, adjustable stirring intensity, and real - time monitoring capabilities. With our professional technical support and after - sales service, we can help you optimize your degumming process and enhance your competitiveness in the industry.

Q: What is the most common mistake in the degumming process?

A: The most common mistake is misjudging the end - point of degumming, which can lead to incomplete degumming or over - degumming.

Q: Can the same degumming parameters be used for all types of oils?

A: No, different oils have different characteristics, so differentiated degumming strategies are needed.